Trees: Magnificent structures

Roland Ennos

How trees stand up: Wood

Like all engineering constructions, trees combine two elements to achieve their magnificent structures: they use good materials and they arrange the materials so that they are used to their best advantage. Trees, have a single, superbly engineered material--wood--and are ingeniously designed structures that combine strength and flexibility. They can even respond to their environment and change their design accordingly. This allows them to support their canopy of leaves using a bare minimum of structural material.

The mechanical design of wood

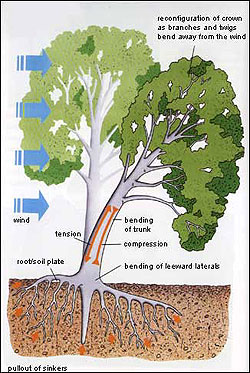

This diagram demonstrates the forces which are set up and movements which occur when a tree is blown sideways by the wind. Trees are ingeniously designed structures that combine strength and flexibility. They can respond to their environment and change their design accordingly. This allows them to support their canopy of leaves using a bare minimum of wood.

Wood needs to combine many useful properties to allow it to support the leaves of trees. It has to be stiff, so that trees do not droop under their own weight; it has to be strong, so that the sheer force of the wind does not snap the trunk and branches; it has to be tough, so that when the tree gets damaged it does not shatter; finally it has to be light, so that it does not buckle under its own weight. No manufactured material could do all of these things: plastics are not stiff enough; bricks are too weak; glass is too brittle; steel is too heavy. Weight for weight, wood has probably the best engineering properties of any material. Its superb properties result from the arrangement of the cells and the microscopic structure of the cell walls.

Arrangement of cells

Over 90 percent of the cells in wood are long, thin tubes that are closely packed together, pointing along the branches and trunk. As well as helping them to transport water to the leaves, this is ideal for providing support because they point in the direction in which the wood is stressed.

Trees mainly have to resist bending forces. Their branches have to resist being bent down under their own weight, and both the trunk and branches have to resist being bent sideways by the wind. These bending forces actually subject the wood inside to forces which are parallel to the trunk or branch; the concave side is compressed, while the convex side is stretched. Whichever way the tree is bent, therefore, the internal forces always act parallel to the cells or 'grain' of the wood.

The long, thin wood cells are well suited to resist the forces; the cells on the concave side resist being compressed, rather like pillars, while those on the convex side resist being stretched, rather like ropes. Consequently, wood is very strong along the grain.

The cellular nature of wood is also advantageous to the tree for another reason. Because the cells are hollow, the tree's trunk and branches can be thicker than if all its wood material were laid down in a solid mass. Weight for weight, tubular structures such as these are stronger than solid structures; this is why tubes are so often used in large engineering structures.

Rays

The arrangement of the cells along the trunk does have one potential disadvantage. It is relatively easy to split wood parallel to the trunk, what a carpenter would call along the grain. However, this is not very important to the tree because its wood is hardly ever subjected to forces in this transverse direction. As an extra precaution, trees prevent the wood splitting between successive growth rings by incorporating into it blocks of cells called rays, which are oriented radially in the trunk. As well as storing sugars, these rays act rather like bolts, effectively pinning the wood together. The result is that when you do see trees that have been split along their length--for instance after they have been struck by lightning--it breaks radially from the centre of the trunk outwards, parallel to the rays. This is also why the way to chop up logs into firewood is to cut it radially, through the centre of the trunk, like cutting pieces of pie.

Structure of the cell walls

Cell walls are made of a composite material and this also improves the mechanical properties of wood. They are made of tiny cellulose microfibrils that are embedded in a matrix. The cellulose fibres stiffen the material while the matrix protects the fibres and prevents them from buckling. This gives the composite a combination of high stiffness and strength.

The arrangement of the embedded fibres within the walls of wood cells helps to make wood even tougher. Wood cells have walls with several layers, but the thickest layer, making up 80 percent of the wall, is the so-called S2 layer. Here the microfibrils are arranged at an angle of around 20 degrees to the long axis of the cell, winding round the cell in a narrow helix. This is not far off being parallel to the cell wall, so they stiffen it up along the grain quite effectively. But the greatest effect is to dramatically increase the toughness. As the wood is stretched the cells do not break straight across; instead, the cell walls buckle parallel to the fibres and the different strips of the cell wall are then unwound like springs. This process creates very rough fracture surfaces and absorbs huge amounts of energy, making wood around a hundred times tougher even than fibreglass. This mechanism acts only when wood is cut across the grain, but it explains why wooden boats are far sturdier than fibreglass ones and can absorb the energy in minor bumps without being damaged.

Pre-stressing of wood

Wood has just one problem; because wood cells are long, thin-walled tubes, they are very prone to buckling, just like drinking straws. This means that wood is only about half as strong when compressed as when stretched, as the cells tend to fail along a so-called compression crease. If a wooden rod is bent, the compression crease will form on the concave side. This will subsequently weaken the rod. Trees prevent this happening to their trunks and branches by pre-stressing them.

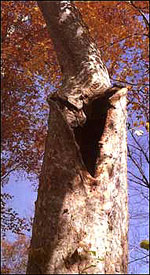

This plane (sycamore) tree Platanus occidentalis, has suffered from brittleheart. As a result, its trunk has become hollow and it is vulnerable to breaking in high winds. (Image: Nancy C Garwood)

New wood cells are laid down on the outside of the trunk in a fully hydrated state. As they mature their cell walls dry out and this tends to make them shorten. However, because they are already attached to the wood inside they cannot shrink and will be held in tension. Because this happens to each new layer of cells, the outer part of the trunk is held in tension, while the inside of the trunk is held in compression. The advantage of this is that when the tree is bent over by the wind, the wood cells on the surface are not actually compressed but some of the pre-tension is released. On the other, convex side the cells will be subjected to even greater tensile forces, but they can cope very easily with those. The consequence is that tree trunks can bend a long way without breaking. This fact was exploited for centuries by shipwrights who made their masts, as far as possible, from complete tree trunks.

Pre-stressing has two unfortunate consequences. Many trees are prone to a condition known as 'brittleheart'. When the wood in the centre of the tree ages it can be attacked and broken down by fungi. Eventually it becomes so weak that the precompression force makes it crumble, and the tree trunk becomes hollow. Another problem occurs when trees are harvested. Cutting the trunk frees the cut end and in some species this allows the pre-stress to be relieved; the centre of the trunk extends and the outside contracts, bending the two halves of the trunk outwards and causing the trunk to split along its length. These splits are known to foresters as 'shakes' and render the timber useless. In some fast-growing species of Eucalyptus the trunk can spring out so violently that it can kill the lumberjack who is cutting it down.

Toolbox

There are 27 km of specimen shelves in the Darwin Centre - the same distance as between the Museum and Junction 6 of the M1.